Eriba Puck / 2003 / Sold

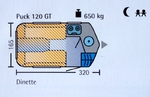

Eriba Puck 120GT / Year 2003.

To be sold via eBay auction. CLICK > here

No 'buy it now' price is available and the auction will be left to conclude. I am not interested in ‘offers’. Will be sold to the highest bidder. Please only participate in this auction if you are serious about buying this Eriba. Feel free to ring me if you wish to discuss the work involved.

UK delivery is available, including Northern Ireland (Belfast port only), also; Ireland, and delivery to Europort NL. Payment in full before delivery.

This Puck is in need of some restoration work to reinstate its potential value of around £7000

Mainly it is in need of some chassis steel work replacing, and some decoration to internal wallboards.

The Puck will make a great winter project for someone with the right skills.

Condition / External:

Aluminium panelling in good condition, a few minor dinks, nothing at all serious

GRP roof in good condition

Windows are all in good condition (blinds working)

Main cruciform galvanised Al-Ko chassis, running gear, wheels and tires (year 2012), all in very good condition

Under-floor plywood area in good condition

Caravan steel frame peripheral box-section member very poor, perforated with rust in several places, needing re-fabrication and replacement

Condition / Internally:

Upholstery in very good condition

Woodwork in good condition

Pop-top fabric in good but slightly stained condition

Headlining is in good condition

Floor covering is in good condition

Wallboards are in good structural condition, but stained in places where water has previously entered probably from a high-level brake light leak left unattended. The boarding shows an average moisture meter reading of 12 to 15%. In other words these areas are no longer damp

Moisture ingress; although the caravan has had previous moisture ingress, damp readings taken from all over the caravan show that there is no longer any moisture present.

The caravan was serviced this year and towed very well over a 200 miles journey.

notes from questions:

To do the rebuild justice, the frame needs to be worked on by removal of the side panels . Some of the rot might be up the vertical risers of the steel 'bird-cage' like frame, but my experience tells me it wont be far up, if at all. The rot in the frame is possibly due to electrolytic reactions, stray currents from a battery left in circuit, and a damp salty environment from winter roads. This type of corrosion is common on steel or aluminium boat hulls, thats why they need sacrificial anodes. Having said that, the aluminium sheet is fine, so I might be talking nonsense!

The wall board staining has been caused by the high-level brake light leaking. As I see this all the time, and know that the damp spreads all over the place.

The caravan was stored on a slight slope, lower part being the left side with the staining. The water would have come in through the massive hole Eriba cut in the roof for the high-level brake-light, the water works its way all over the place, even appearing at floor level as well as waist level.

Pop top material is good but stained. This is very common. Lock the caravan down when damp, even after using, and the material can get mildew. The mildew does not rot the material and can be cleaned off and then reproofed.

................................................................

You should be able to do the work without

any issues. To make a professional job of it, the lower aluminium side panelling needs to be removed from the frame. This then allows you access to work on the corroded

areas.

To take the side panelling off you take both

horizontal aluminium trims off, that is; the waist level trim and a lower level trim. These simply unscrew once the plastic insert is removed. Under this aluminium trim is a mastic backing layer.

This is not difficult to take off as it is permanently soft, the mastic is a butyl type. The aluminium panels are pop riveted and screwed along the line were you have just taken off the horizontal

aluminium trim and backing. Once the screws and pop rivets are removed the panels can be carefully taken off and stored. It is then relatively straightforward to fabricate the pieces of the frame

that need to be replaced. Once these new sections are in place the aluminium panels and trim go back in reverse order.

Like most work of this nature it requires time

and patience, as well as a good working environment. The cost is minimum in terms of parts, and high in terms of labour. This is why I do not attempt such work myself. I have carried out a few of

these rebuilds and they take up too much of my time.